Market Overview

India’s long-term growth is based on a young and rapidly expanding population that is boosting economic activity and creating a large, urban middle class. This is generating interest in modern home furnishings and interiors, trends that are driving steady growth in the demand for wood.

With declining availability of traditional hardwoods, Indian manufacturers are seeking alternate wood supply sources.

The result has been a rapid shift towards softwoods, which presents a unique opportunity to position B.C. and Canada as a reliable supplier of fibre from sustainably managed sources.

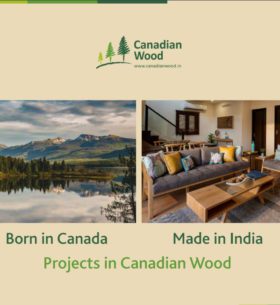

Photo: Hemlock product trails, Bramola | Credit: FII India