Premier David Eby and Ravi Kahlon, Minister of Jobs and Economic Growth, recently led a trade mission to India as part of the Look West Strategy to diversify trade and grow exports. One of the mission’s primary goals was to showcase B.C.’s leadership and capabilities in the province’s resource sectors, including sustainable forestry.

To support this, FII India organized a forestry roundtable and a site visit to Morph Design Company in Bengaluru, the luxury interiors and furniture brand of Prestige Group, to highlight B.C.’s forest products and explore opportunities for collaboration with India’s manufacturers, designers, and builders.

The roundtable brought the B.C. government officials together with Indian leaders from furniture manufacturing, wood importing, and the architecture and design community. Discussions focused on long-term commercial cooperation, aligned with India’s growing demand for imported wood products—driven by urbanization, rising incomes, and the expansion of furniture and interior manufacturing.

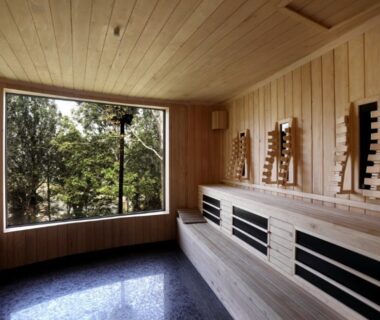

Participants explored how B.C.’s sustainably managed forest products can support furniture, premium residential, hospitality, and emerging structural applications, sharing insights from recent projects and identifying opportunities as India’s design and manufacturing capabilities evolve. Indian manufacturers and designers also highlighted how certified, responsibly sourced B.C. softwoods meet buyer expectations for quality, durability, and environmental responsibility.

Following the roundtable, Minister Kahlon visited Morph Design Company. Morph Design specializes in premium doors, modular furniture, and interior solutions, leveraging automated production and eco-friendly materials. Its Bengaluru facilities produce more than 7,000 door sets each month, supported by imported Douglas-fir. During the visit, Minister Kahlon and Morph’s leadership team explored how B.C.’s sustainably sourced wood can further support India’s growing high-end residential, commercial, and hospitality sectors.

Since 2014, FII India has been supporting the growth of B.C. softwoods in India’s manufacturing sector. Through initiatives such as workshops, technical guidance, product trials, and partnerships with local stockists, FII India helps manufacturers and designers select the right species and optimize their use in furniture, interiors, doors, and other high-visibility projects. These efforts strengthen market awareness of B.C. wood, facilitate commercial collaboration, and reinforce the Canadian Wood brand to meet growing demand in both domestic and export-oriented markets.

The forest products section of the mission highlighted the strong potential for B.C. wood in India’s growing manufacturing and construction sectors. By connecting B.C.’s sustainably managed forest resources with India’s evolving design and production capabilities, these engagements provided opportunities for long-term collaboration, innovation, and growth.